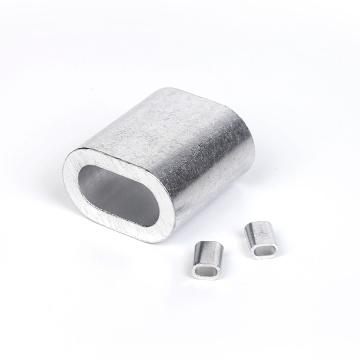

Aluminum Sleeve

(Total 8 Products)-

Brand:CHENGLUMin. Order:1 TonTransportation:Ocean,LandPlace of Origin:CHINAAluminum Oval Wire Rope Sleeve: Precision Connection, Solid Safety Line In the world of industrial connections and lifting fastening, every component carries the dual mission of safety and efficiency. The aluminum oval wire rope sleeve, as a core...

-

Brand:CHENGLUBUXIUGANGMin. Order:1 Piece/PiecesTransportation:OceanPlace of Origin:CHINAStainless Steel Rope and Cable Aluminum Sleeves: Long-Lasting and Durable Protection Solutions Stainless Steel Rope Aluminum Sleeves and Stainless Steel Cable Aluminum Sleeves are designed to provide superior protection and durability for a variety...

-

Brand:CHENGLUMin. Order:1 TonTransportation:OceanPlace of Origin:CHINAThe main function of Aluminum Crimping Loop Sleeve is to protect the wire rope, reduce wear and extend its service life. Specifically, Aluminum Sleeve can provide effective protection during the use of the wire rope through its structural design to...

-

Brand:CHENGLUMin. Order:1 TonTransportation:OceanPlace of Origin:CHINAThe main function of Aluminum Crimping Loop Sleeve is to fix and protect the wire rope, while enhancing the load-bearing capacity and service life of the wire rope. Aluminum Crimping Sleeves are usually made of a combination of wire rope and...

-

Brand:CHENGLUMin. Order:1 TonTransportation:OceanPlace of Origin:CHINAThe main functions of Aluminum Crimping Loop Sleeve include: fast heat dissipation, light weight, and good comfort. The thermal conductivity of aluminum alloy is 3 times greater than that of steel. It can quickly transfer the heat generated by...

-

Brand:CHENGLUMin. Order:1 TonTransportation:OceanPlace of Origin:CHINAThe main functions of Aluminum Sleeve include fixing the formwork, controlling the thickness of concrete pouring, bearing loads such as the lateral pressure of concrete, and ensuring that the distance between the internal and external formwork meets...

-

Brand:CHENGLUMin. Order:1 TonTransportation:OceanPlace of Origin:CHINAThe main functions of Aluminum Sleeve are to fix the formwork, control the thickness of concrete pouring, serve as the fulcrum of the formwork and its supporting structure, and ensure that the spacing between the internal and external formwork meets...

-

Brand:CHENGLUMin. Order:1 Piece/PiecesTransportation:OceanPlace of Origin:CHINAThe advantages of Aluminum Crimping Loop Sleeve for wire rope slings are mainly in the following aspects: High bonding strength: The aluminum sleeve has a high bonding strength with the wire rope. Even if the wire rope breaks, the Aluminum Crimping...

Aluminum Sleeve

Aluminum sheaths are commonly used for a variety of purposes, and their main functions and effects depend on the specific application scenarios. Here are some common application scenarios and their effects:

1. Cable protection: In cable engineering, aluminum sheaths are used to wrap cables to provide physical protection and prevent damage to the cables from the external environment (such as water, chemicals, mechanical damage, etc.).

2. Construction industry: Aluminum sheaths are sometimes also used as part of building materials, such as in certain types of building structures or decorations to take advantage of the lightweight and corrosion-resistant properties of aluminum materials.

3. Pipeline systems: In some piping systems, aluminum sheaths can be used as part of the pipe to connect different parts or increase the stability of the piping system.

4. Industrial applications: In the industrial field, aluminum sheaths may be used to make various components, such as machine parts, tools, etc., because aluminum materials have a good strength-to-weight ratio and corrosion resistance.

5. Electrical engineering: In electrical engineering, aluminum sheaths may also be used as the outer layer of conductors or as a conductive material in some cases, although copper is more commonly used for conductive purposes.

Please note that the specific aluminum sheath application and its role will vary depending on actual needs and designs. If you have a specific application scenario you would like to know about, please provide more details so that we can give you a more accurate answer.

1. Cable protection: In cable engineering, aluminum sheaths are used to wrap cables to provide physical protection and prevent damage to the cables from the external environment (such as water, chemicals, mechanical damage, etc.).

2. Construction industry: Aluminum sheaths are sometimes also used as part of building materials, such as in certain types of building structures or decorations to take advantage of the lightweight and corrosion-resistant properties of aluminum materials.

3. Pipeline systems: In some piping systems, aluminum sheaths can be used as part of the pipe to connect different parts or increase the stability of the piping system.

4. Industrial applications: In the industrial field, aluminum sheaths may be used to make various components, such as machine parts, tools, etc., because aluminum materials have a good strength-to-weight ratio and corrosion resistance.

5. Electrical engineering: In electrical engineering, aluminum sheaths may also be used as the outer layer of conductors or as a conductive material in some cases, although copper is more commonly used for conductive purposes.

Please note that the specific aluminum sheath application and its role will vary depending on actual needs and designs. If you have a specific application scenario you would like to know about, please provide more details so that we can give you a more accurate answer.